«Дэйримаш» является

официальным дилером компаний FIBOSA и FINOVA

(Испания) на территории РФ.

ГК «Дэйримаш ЗММ и ПО» является партнером абсолютного лидера среди компаний, занимающихся лизингом в сфере сельского хозяйства — АО «Росагролизинг».

«Дэйримаш» стала первой аккредитованной компанией в сфере пищевого машиностроения для предоставления максимально выгодных условий лизинга, обеспечения доступности инновационных технологий российского производства.

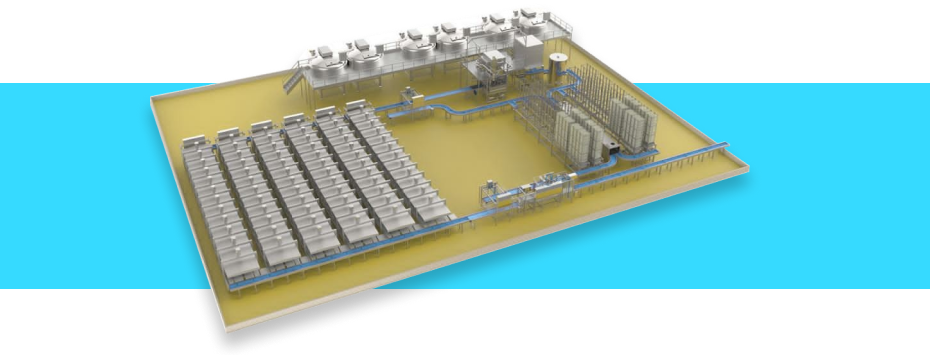

«Дэйримаш» обеспечивает предприятия оборудованием для переработки молока, автоматизированными линиями производства сыра. Реализует комплексные проекты молокоперерабатывающих заводов с объемом переработки от 10 до 500 тонн молока в сутки «под ключ».

экосистема дэйримаш